In 2011, we have first executed our Solar Module Mounting (MMS) design with field prototyping. From then we have learned and mastered the art of MMS design with optimized weight to stability and strength of MMS. Below is the case study of one of the MMS designed for wind loads at 47m/s (~169Kmph), We have carried out the flow and Structural simulations of the structure thereby verifying the strength according to IS-801 and IS-800 criteria.

Need for Computational Fluid Dynamics (CFD)

The guidelines of IS-875 part 3 seems to be misused or misinterpreted for the lower weight of the structures but it has been seen that even though the structure is said to be verified with structural analysis packages, the failures of MMS at sites lead us to have some in-depth understanding of the wind flow pattern and load values. There are currently two ways to understand this, first is wind tunnel testing and other is Computational Fluid Dynamics (CFD).

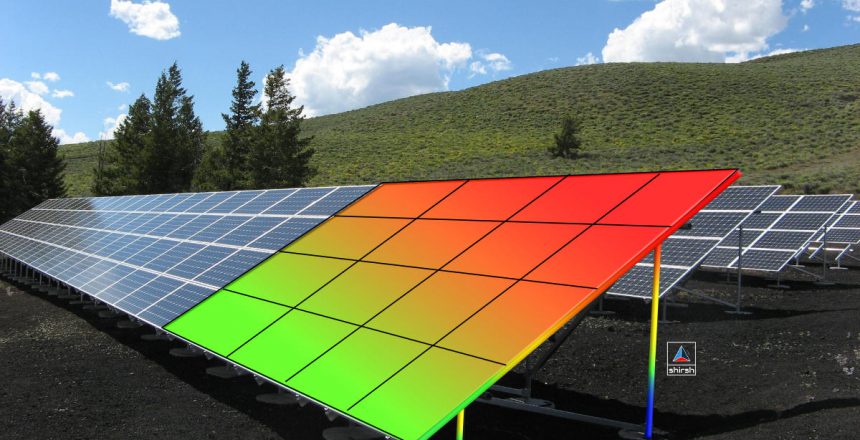

Now the wind tunnel test has its own challenges and may be done for the final designed MMS rather than conducting on each design iteration. Here the CFD tools come in handy which will not only predict wind flow pattern but also pinpoint the load variation on the panel surfaces. Apart from the static loads but CFD will also calculate the wind oscillations, the Vortex Shedding effects, and most importantly the wind study from different directions is a key to stable and robust Solar MMS designs.

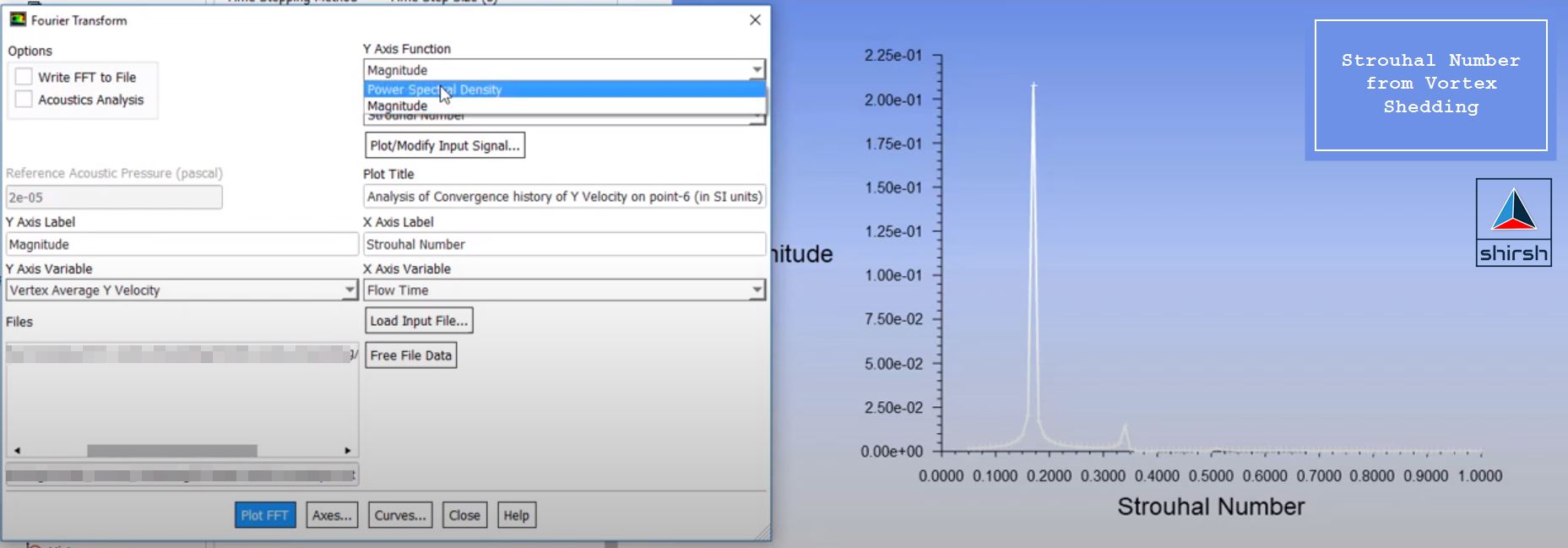

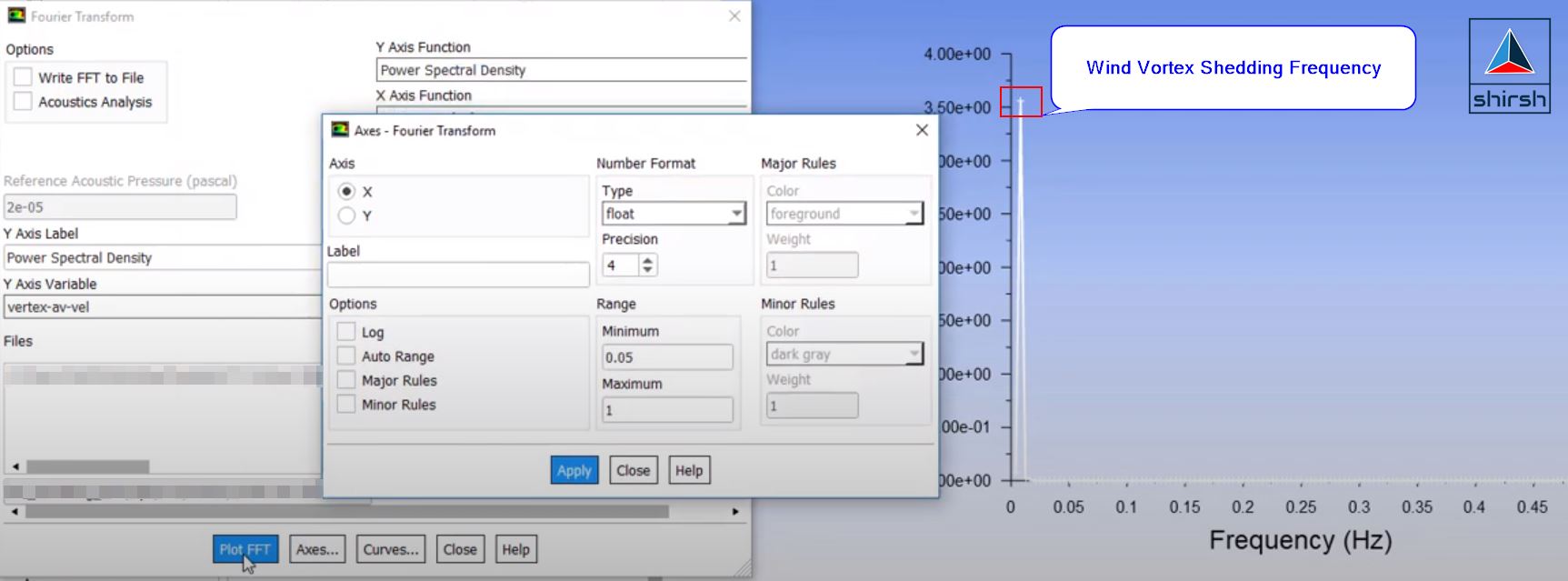

The design wind speed as per IS 875-part 3 for most of the regions in India is 47m/s where this Solar MMS is being installed. In such a climate, the critical wind speed to have vortex shedding to match the fundamental frequency of the structure can be expected to occur several times per year if the fundamental frequency is less than 1Hz, which is also true if the fundamental frequency is above the 1Hz limit as set by general guidelines of IS 875 part 3 clause 9.1. So the guidance provided may mislead the engineer to dismiss the dynamic issues which in many cases is the pertaining issue for failure.

Analyses Approach

Based on the inputs such as location, topography and base MMS layout, we have conducted CFD study. Below is the animation for the same. We conducted

- Wind Flow analyses with different wind directions

- Studied the vortex shedding and calculated Strouhal Number (St)

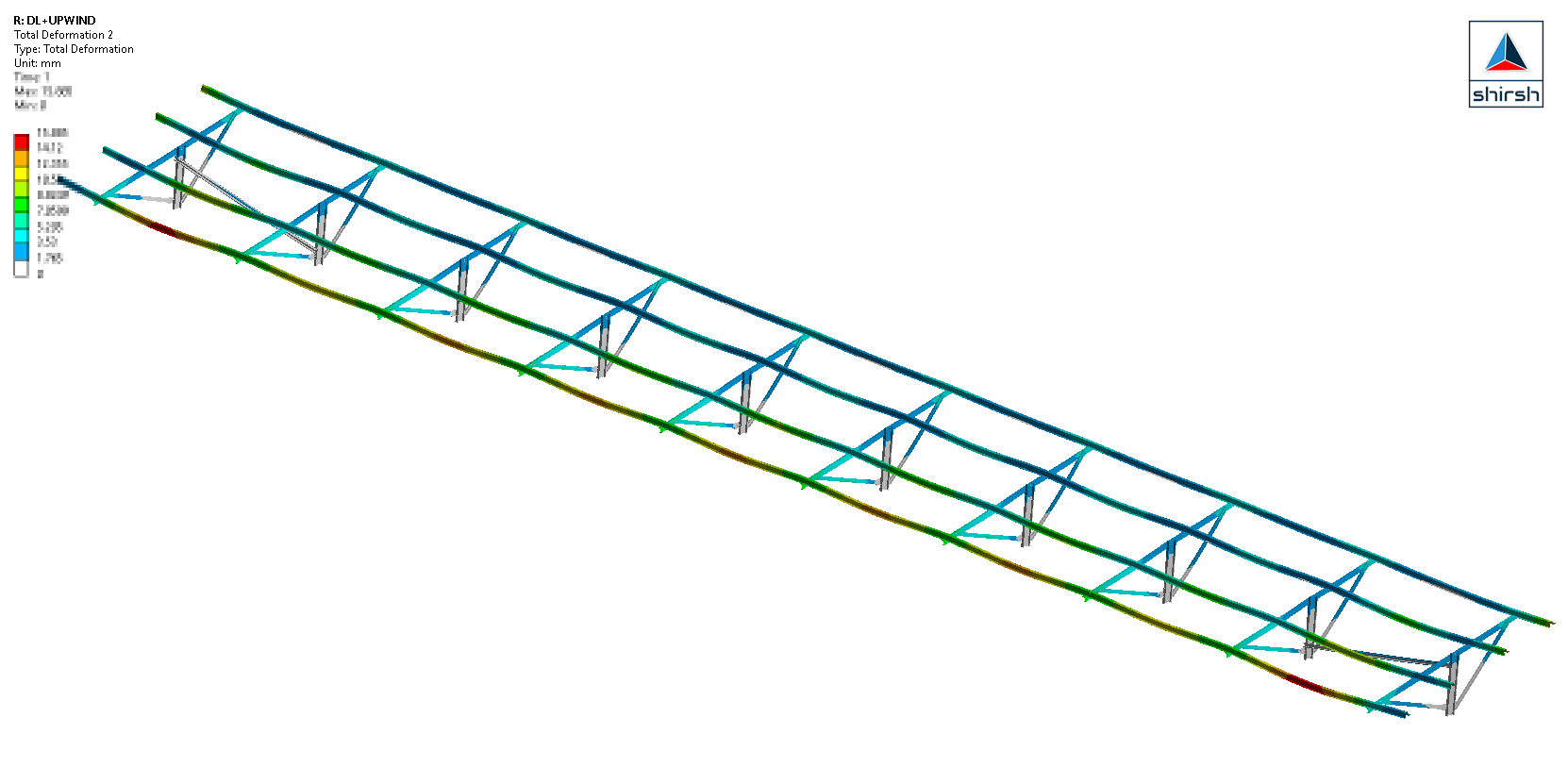

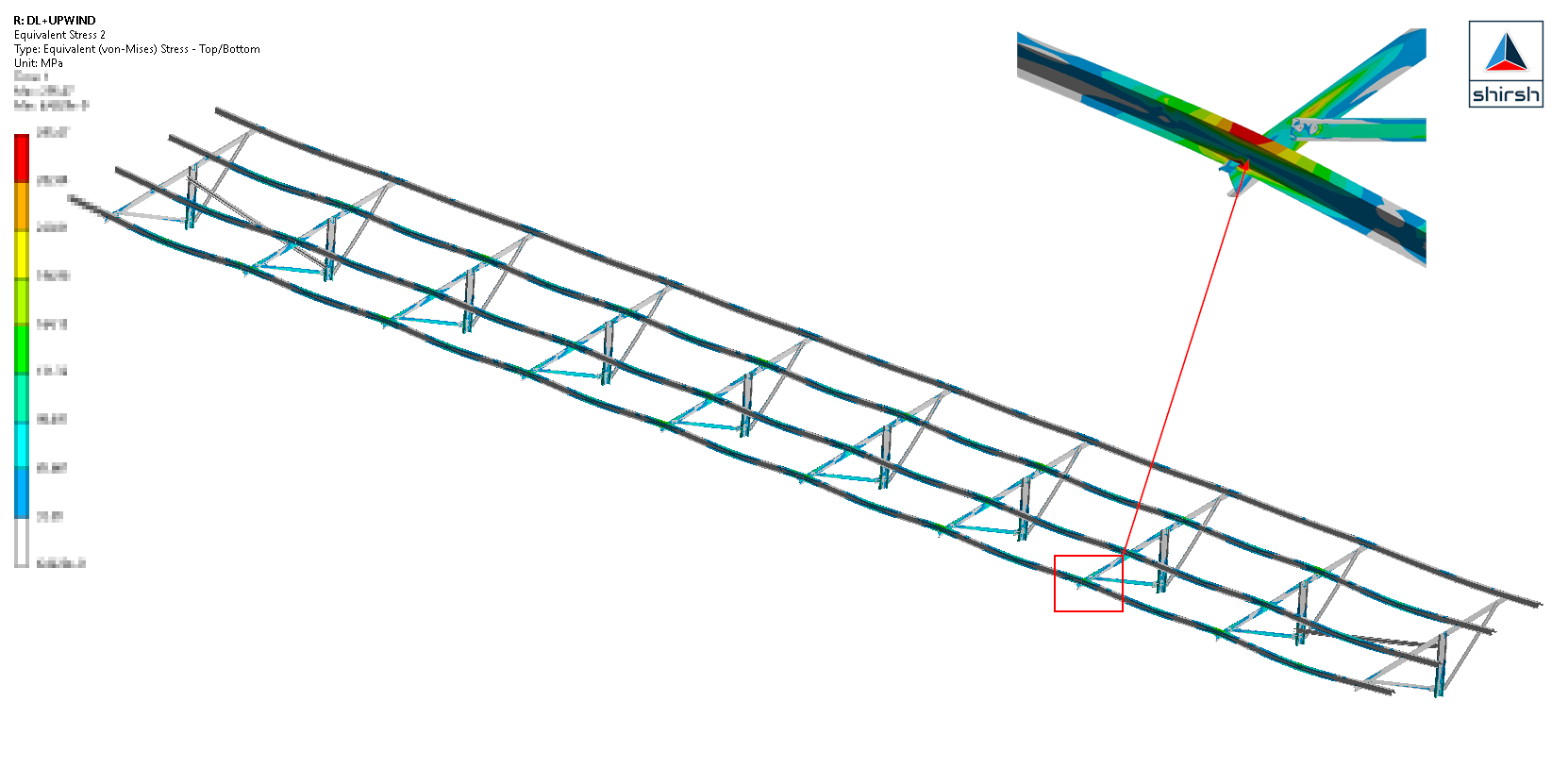

- Then Structural analysis was done with pressure mapping from CFD study

- Followed by Structural Dynamic Simulation for structural response to it.

Outcome of the Analysis

After the Numerical simulations we worked on the parameter optimization for understanding the optimum MMS design, The structure was optimized for robust design environment and sustain local buckling too.