Project Brief

Conducting a 3D steady state CFD analysis of a defense product to study temperature variation and identify hotspots in electronic components with heat dissipation and a cooling system.

Challenges and Objectives

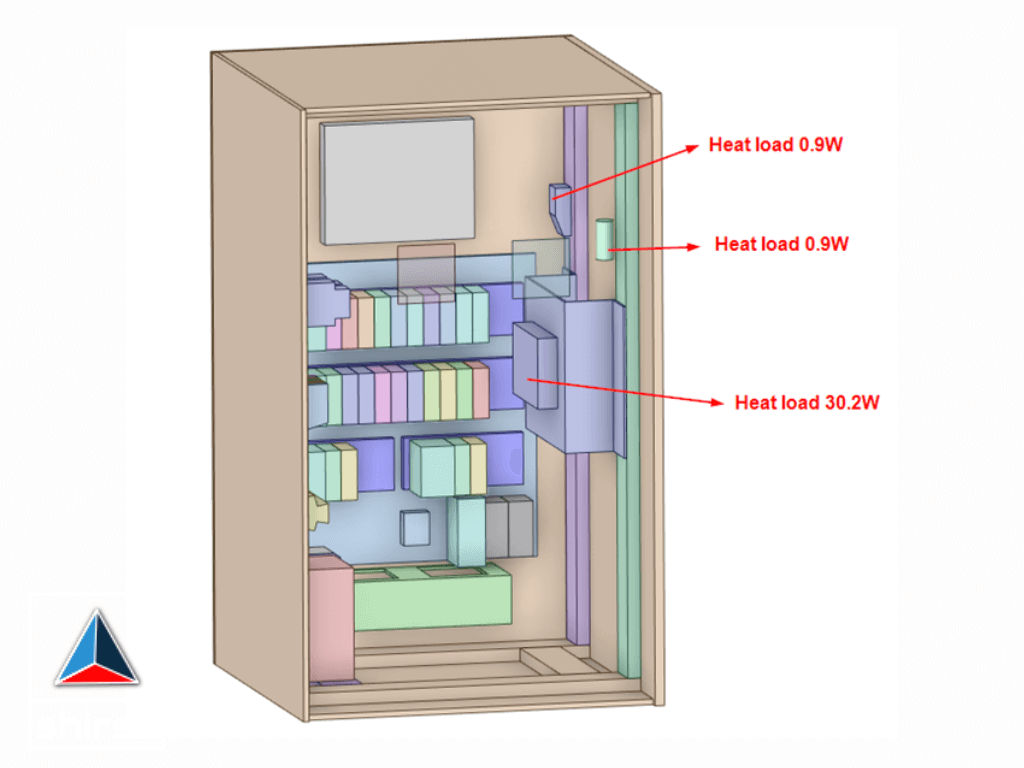

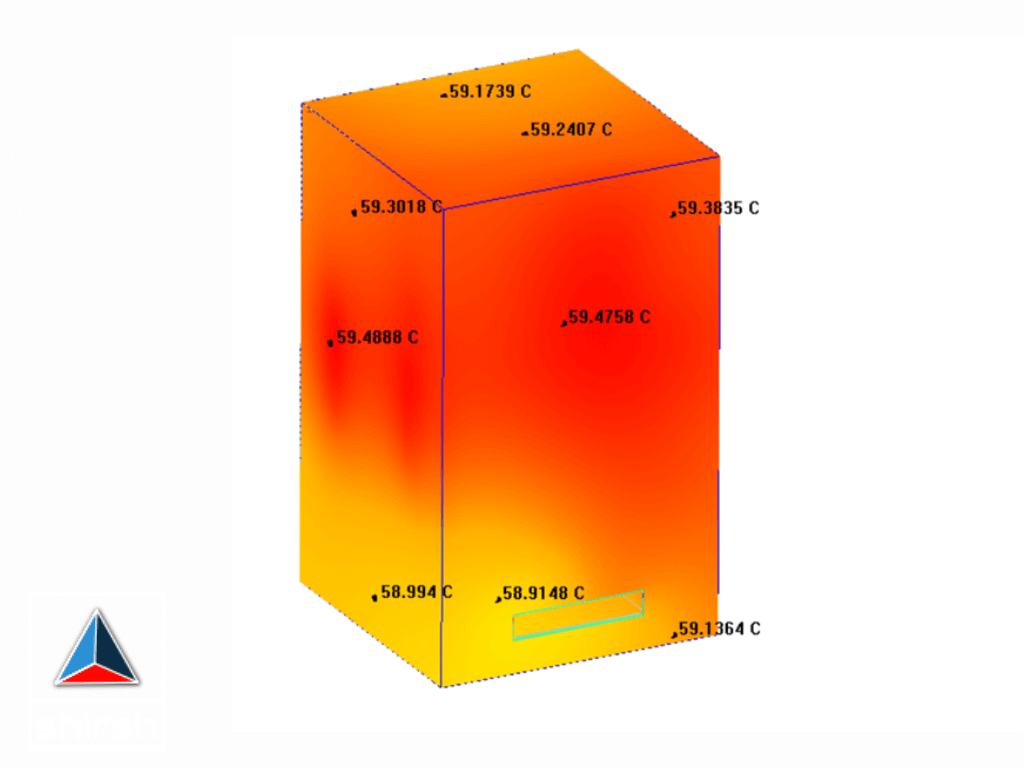

The client sought to analyze the temperature distribution in their defense product due to heat dissipation from electronic components and ensure the efficient functioning of the cooling system. The main challenge was to identify temperature hotspots to prevent component damage and enhance product reliability.

Methodology (Solutions Implemented)

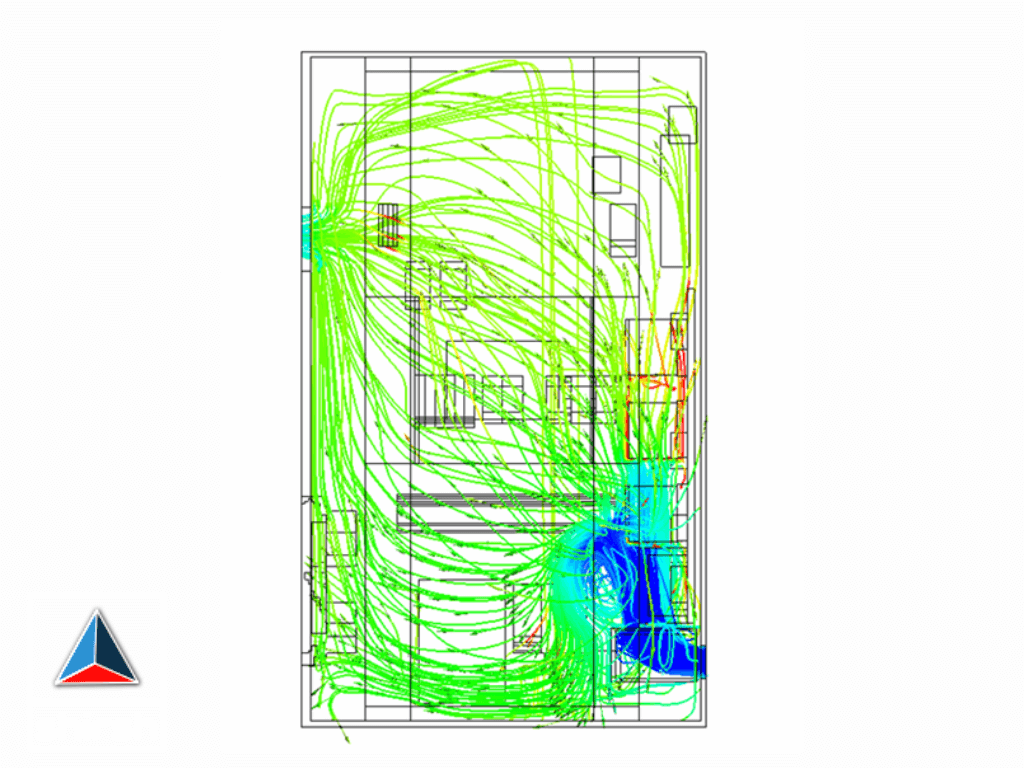

Using a 3D CAD Model, boundary conditions such as heat load in electronic equipment, ambient air temperature, and cooling system details were set along with fan curve. CFD analysis was performed to simulate the temperature distribution and ambient air velocity across the domain and around the electronic equipment.

BENEFITS (RESULTS ACHIEVED)

The analysis successfully identified temperature hotspots in the system, allowing the client to make informed decisions for improving heat dissipation and cooling efficiency. Quantifiable data revealed a significant reduction in temperature variations, ensuring the products reliability and performance.

Summary of Project

By leveraging CFD analysis, the client gained valuable insights into the thermal behavior of their defense product, enabling them to optimize the design for better heat management and overall performance. The project showcased the effectiveness of CFD in improving product reliability and efficiency in electronic systems.